条纹T恤

Barred Tee

A barred tee is a tee or any fitting with a branch used in pipelines that is pigged and has a restriction bar welded internally preventing the pig from traveling down a branch connection.

Barred tee is a pipe fitting that is used in a pig launcher or receiver system in a piping system to ensure the pig could pass the branch safely.

Barred Tee for long distance submarine oil and gas pipeline.

Design considerations for barred tee

- The barred tee will be used when there is a requirement for pigging. Thus, many of its applications can be found in the pipeline or in the subsea field.

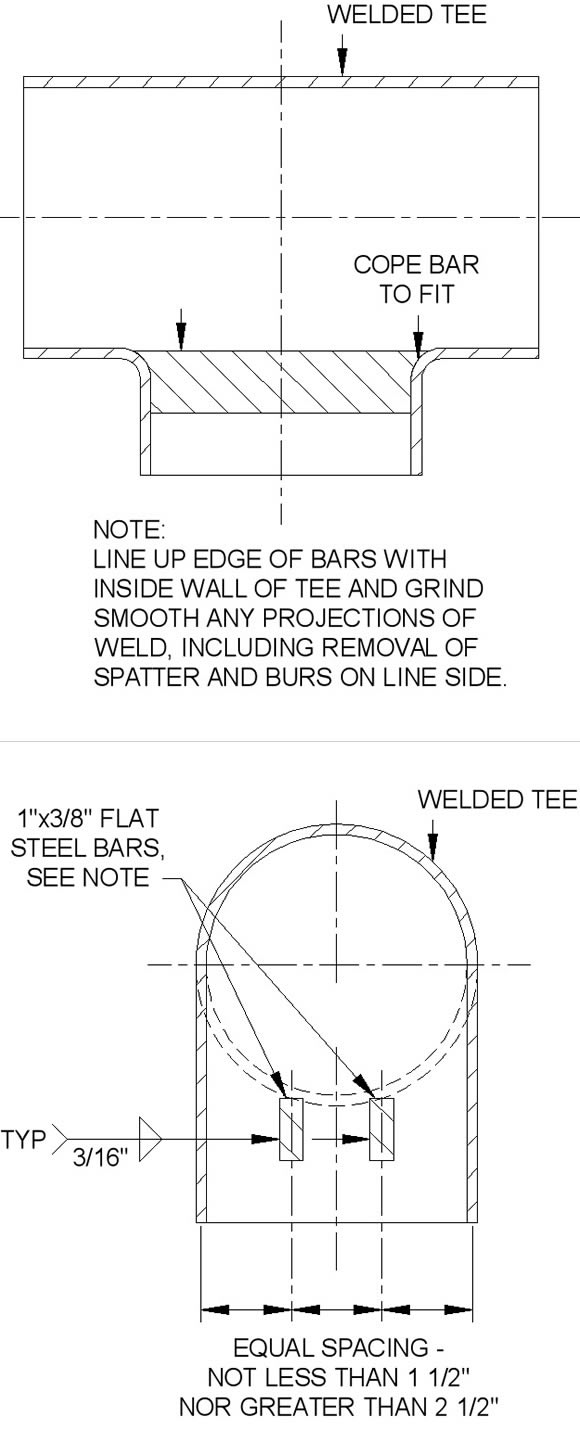

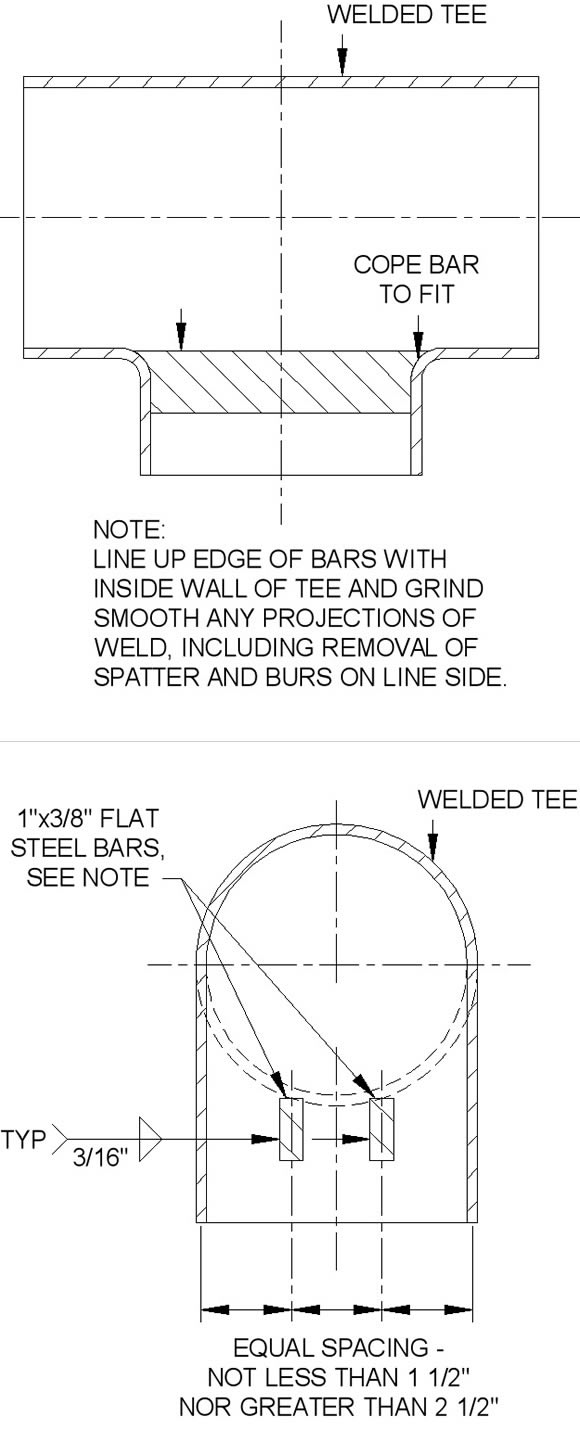

- The bar plates that welded internally at the branch are to avoid the pig from changing direction or getting stuck at the branch outlet.

- The design of the bar plates must be in sufficient quantity, thickness and adequately spaced to ensure the smoothness for the pig to run through the main pipe, and at the same time not affecting the flow that was meant to flow through the branch. Normal practice is to ensure that the opening in the branch pipeline after guided bars is not more than 40% of the main pipeline area.

- The size of the bars in the branch connection has to be small enough not to restrict the flow but large enough to sustain the pressure of the flow.

- To ensure the smoothness, the bar plates have to be a grind to suit the branch curvature. Any sharp edges, spatters and burs are required to be removed. This smoothness of the pigging process is important to protect the sensor of the pig from damage.

- Refer to Shell DEP 31.40.10.13-Gen Figure 4 above; the quantity of the bar plates start with two (2) pieces and increase as the ID of the branch increase.

- The bar plates ideally will be equally spaced.

- For larger tee (size 14 inches and above), there will be a bridge plate in the middle to support the bar stiffness when getting hit by the pig.

- The material of the bar plates commonly used the same as the tee material for weldability.

- Standard practice is to avoid welding of guide bars directly on the high-stress concentrated areas of the extrusion neck. Bar ends must be machined to fit the branch.

- Weld Repairs on Parent metal is prohibited.

Barred tees are pipe fittings with two outlets, one at 90 ° to the connection to the main line that has tiny holes. Barred tees can either be extruded or fabricated and are used to connect two pieces of pipe or fittings. Barred tee is used in pipelines that are pigged.

Datasheet of a pipe barred tee

Difference between tee and barred tee

Tee or Tee connection in piping engineering is a very important pipe fitting and is frequently used to combine or divide a flow. Two types of Tee are available, Equal Tee and Reducing Tee. However, in pigged pipelines, one special type of tee connection is widely used which is known as Barred Tee or Pigged Tee.

So from the above discussion, we can summarize the following differences:

| Parameter | Tee | Barred Tee |

| Definition | Standard Pipe Fitting | A special type of piping component |

| Manufacturing | Generally by Extrusion or forging | Mostly Fabricated |

| Use | Used in both piping and pipeline engineering | used in pipeline engineering near the pig launcher/receiver |

| Design Code / Standard | ASME B 16.9/MSS SP 75 | Shell DEP 31.40.10.13-Gen or ISO 15590-2 |

| Production Quantity | Large scale in bulk | Select small quantities (custom made) |

| Cost | Cheaper | Costlier than normal Tee |

Tee vs Barred Tee

Tee is a type of fittings that allows fluid to flow on its main pipe and branch out. The branch can be designed equally the same size as the main pipe (known as Equal Tee), or smaller size than the main pipe (known as Reducing Tee).

Barred Tee is a special type of Tee that base from a normal tee (can be either equal tee or reducing tee) that at later stage, will be added with bar plates inside the branch outlet (From inside it looks like a steel cage) to restrict the pig from flowing from the header pipe into the branch pipes.

Common types of pipe tee

A pipe tee is a type of fitting that has a T shape and is used to join two or more plumbing pipes.

- Equre tee (or straight tee), means the branch diameter of this tee is same with the main pipe (Run pipe) diameter of this tee.

- Reducing tee is a type of pipe fitting in which the branch port size is smaller than the ports of the run.

- Barred tee is used in pipelines that are pigged.

- Lateral tee has a 45 degree branch from a pipeline.

- Pipe cross is a fitting that used in the place where four pipes meet with the same diameter include:

- Reducing cross used for connecting four pipes, the main pipes with the same size, but the dimensions of the branch diameter is smaller than the main pipes.

- Equal cross in the place where four pipes meet with the same diameter.

- Forged Tee Fittings are pipe fittings that be formed mainly by forging.

Size range: 1/2 to 72 inches

Pressure: SCH5 to SCH160

Materials

- Carbon steel: ASTM/ASME A234 WPB-WPC

- Alloy steel: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP 911

- Stainless steel: ASTM/ASME A403 WP 304-304L-304H-304LN-304N

- ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti

- ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H

- Low temperature steel: ASTM/ASME A402 WPL 3-WPL 6

- High performance steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70

Welding Bevel acc. to standards:

- ASME B16.9, Factory-Made Wrought Steel Buttwelding Fittings

- ASME B16.28, Buttwelding Short Radius Elbows and Returns

- ANSI/ASME B16.25, Buttwelding Ends

- MSS SP-97, Socket Welding, Threaded, and Buttwelding Ends

- Tolerance For butt Welding Fittings

Industrial Processes :

Bending, squeezing, pressing, forging, machining and more

Features of Pipe Tee:

- There are three female openings in a T shaped pipe tee.

- There are straight pipe tees which have the same size openings.

- Reducing pipe tees have one opening of different size and two openings of the same size.

- There are sanitary pipe tees which are used in waste lines. These kind of pipe tees have a curved branch which is designed for a clean out plug. They are used to prevent obstruction of waste.

- A cross pipe tee has four equal sized female openings.

- A wing pipe tee has lugs to fasten the fitting to a wall or stud.

- A compression pipe tee uses compression fittings on two or more ends.

- A test pipe tee has a threaded opening. This opening is used in conjunction with a threaded plug for a clean-out opening on a drain pipe.

Related products of pipe tee:

- Saddle previously is the ventilation ducts 'crotch tee', its shaped like pants, there Equal and unequal diameter, the formal name is "tube tapered pants tee."

- Saddle previously DIN2618 is to replace the existing tee fitting, the use of flexibility, praised by domestic and foreign markets.

- Stainless steel Tee is T-shaped pipe fittings with two outlets, one at 90° to the connection to the main line by stainless.

- Tees straight and reducing- The primary purpose of a Tee is to make a 90° branch from the main run of pipe.

- Wear-resistant Alloy Composite Pipe Tee

- Ceramic lined composite Y-type Tee

- Ceramic lined composite pipe tee

- Aluminum corundum lined lateral wye

- Bi-metal clad lateral wye

Applications of pipe tee:

Pipe Tees are widely used in various commercial and industrial applications. Industrial applications include:

- Chemical processing

- Petroleum

- Pulp/paper

- Refining

- Textile

- Waste treatment, Marine

- Utilities/power generation

- Industrial equipment

- Automotive

- Gas compression and distribution industries

- Pipe Tees are also recommended for industrial plant fluid power systems.

We are manufacturer of Reducing tee and supply high quality Reducing tee in both large and small quantities worldwide &

offer you the best prices in the market.

We have a team of experienced professionals with years of experience in manufacturing.