Self-propagating high-temperature synthesis (SHS) is a method for producing both inorganic and organic compounds by combustion-like exothermic reactions in solids of different nature.

A variant of this method is known as solid state metathesis (SSM). Since the process occurs at high temperatures, the method is ideally suited for the production of refractory materials with unusual properties, for example: powders, metallic alloys, or ceramics with high purity, corrosion–resistance at high–temperature or super-hardnessity.

In its usual format, SHS is conducted starting from finely powdered reactants that are intimately mixed. In some cases, the reagents are finely powdered whereas in other cases, they are sintered to minimize their surface area and prevent uninitiated exothermic reactions, which can be dangerous. In other cases, the particles are mechanically activated through techniques such as ball milling, which results in nanocomposite particles that contain both reactants within individual chemical cells. After reactant preparation, synthesis is initiated by point-heating of a small part (usually the top) of the sample. Once started, a wave of exothermic reaction sweeps through the remaining material. SHS has also been conducted with thin films, liquids, gases, powder–liquid systems, gas suspensions, layered systems, gas-gas systems, and others. Reactions have been conducted in a vacuum and under both inert or reactive gases. The temperature of the reaction can be moderated by the addition of inert salt that absorbs heat in the process of melting or evaporation, such as sodium chloride.

That extra energy (such as electric heating or laser) trigger the igniter combustion, causing the reaction material (solid phase and gas phase a solid - solid, liquid, and with equal) spontaneous reaction, heat release temminick high-speed, reaction by local automatically in the form of combustion wave spread the system, finally obtain a new technology of synthetic material.Powder directly stick each other reactants can be element or elements of powder and gas, also can use a mixture of metal oxides and reductant and non-metallic powder reaction generates heat to maintain ongoing, reaction products must be stable compounds. This technology has high product purity, simple equipment, low energy consumption, 'the advantages of flexible production, fault is a strict process parameters are controlled.Hundreds of compounds have been prepared by this method, such as nitrides, carbides, borates, silicides, oxides, hydrides and so on of various metals.S} -is technology has developed into SH5 powder making technology, SHS sintering technology, 5H5 compaction technology, 5HS melting casting technology, 5H5 welding technology, SHS coating technology, etc.

Any combustion of a chemical substance as long as the result is the formation of a product or material of a practical condensed matter can be called a SHS process.In the SHS process, the substance involved in the reaction may be in a solid, liquid or gaseous state, but the final product is usually a solid state.

Basic requirements for combustion synthesis:

(1) the use of chemical reaction to exothermic, completely or partially without external heat source;

(2) the products of the required components and structures are obtained through the self-sustaining reaction of rapid automatic wave combustion;

(3) control the speed, temperature, conversion rate and composition and structure of products by changing the release and transmission speed of heat.

The products prepared by SHS technology have high purity, low energy consumption and simple process. The non-equilibrium, non-stoichiometric ratio and functional gradient materials can be prepared by SHS technology.

Its features are:

Gamma is a fast synthesis process;

Carbon dioxide has energy-saving effect.

Torque can improve the purity of synthetic materials.

Waste products tend to form porous tissue;

The microstructure of char combustion products has greater dispersion.

Therefore, it is the key to ensure the industrialization of SHS to explore the combustion and synthesis rules of various SHS systems and obtain uniform tissue.

SHS powder synthesis involves a process similar to powder metallurgy.But there are differences between the two, the main difference in the synthesis process.

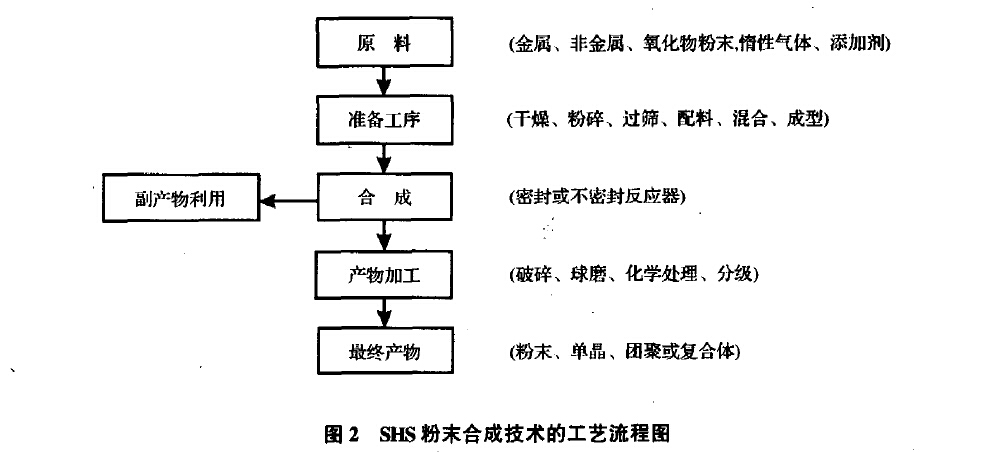

The process flow of HS powder synthesis technology is shown as follows: