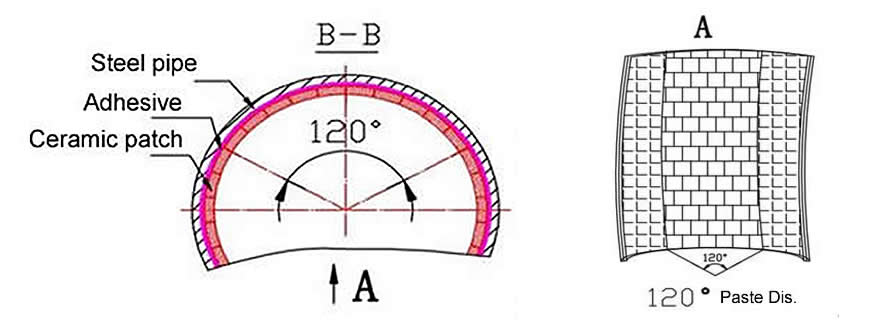

Ceramic Tile Lined Pipe has very uniform coating of specially formulated ceramic material that is affixed to the inner of the pipe and gives a very smooth surface.

Outer of straight pipe is common steel pipe, cladding realized by forming high chromium lining via centrifugal forming technique.

Ceramic tile lined pipe is our company to absorb similar products at home and abroad on the basis of advanced technology developed a shell for the steel body, within the wear-resistant ceramic tube of the new composite pipe products, with high wear resistance long service life And so on

Bimetallic composite steel pipe basic principles: outside the tube is responsible for the pressure and the role of rigid support pipe, liner bear the role of corrosion resistance.

The outer tube can be used according to the flow and pressure requirements of the conveying medium, choose the carbon steel pipe with different diameter and wall thickness, hot-dip galvanized steel pipe, straight seam welded pipe, spiral pipe, low pressure medium pipe, high pressure boiler, Oil cracking with seamless pipe, pipe and so on. Diameter from φ20-φ1020mm, wall thickness from 2.5-50mm.

Can be austenitic stainless steel 304,304 L, 316,316 L, copper-based alloy, nickel-based alloy, Hastelloy, titanium, titanium alloy, duplex stainless steel and other new high corrosion resistance alloy material. The lining wall thickness can be based on service life and welding process requirements from 0.3-4mm.

Will be assembled inside and outside the tube placed in the sink, the cluster of explosives placed in the lining liner axis, through the explosive instantaneous production of explosive force, causing the water pressure within the tank increased instantaneously, instantaneous increase in water pressure, Tube in the direction of outward expansion, outward expansion of the liner under the action of water pressure, the expansion of the outer surface of the outer tube, and under the action of water pressure, with the external tube continued to expand until the pressure disappeared ; And the outer tube in the axial direction inward contraction, the final composite forming.

① one-time instant forming.

② the pressure of the points are basically the same.

Ceramic tile lined pipe and Bend are cast with mold vanishing vacuum suction casting cladding process. Outer of straight pipe is common steel pipe, cladding realized by forming high chromium lining via centrifugal forming technique. Outer of bend uses hot-bending bend and lining is cast with high-chromium cast iron.

Bends and other profile sections can be cladded in whole and this process has changed the traditional practice to fabricate bend and other profile sections by drawing polyline without changing flow pattern of material inside piping,greatly reducing conveyance resistance of material.

① due to the outer surface of the outer tube irregular, resulting in the outer wall thickness is not uniform.

By the Ceramic tile lined pipe forming the basic constraints, to make the outer tube in the elastic deformation range, uneven outside the tube wall thickness, making the mass production, in the loading of explosives, the amount is limited. The dose is small, the impact of a large wave, the outer tube is prone to permanent deformation, or even unsafe, making the binding force but decreased; the amount of small, the impact of small, lined with less than a one-time full plastic deformation, resulting in double Metal composite pipe adhesion is usually about 0.5MPa. Due to the characteristics of the explosive forming process, the liner liner is shrunk inward in the axial direction. In order to ensure that the nozzle round, had to be second correction.

② due to the small binding force, so that the inner and outer tube ring joint surface gap, lining pipe in the pipe end welding, will repeatedly bear the process of media transmission, alternating pressure changes in the reverse, bending, resulting in the connection material fatigue, cracking , Resulting in decreased corrosion resistance - (Finged phenomenon).

③ due to the amount of loading explosives are limited, the liner does not reach the full plastic deformation.

As the reaction force generated by the shock wave is small, the inner surface of the liner pressure is not fully reflected, the liner straight seam welding is still in the state of tensile stress. Resulting in the liner surface as a whole, especially the straight seam welding, the ability to resist thermal stress corrosion.

Binding force:

That is, the degree of integration of internal and external pipe, Ceramic tile lined pipe is the most important test indicators.

Ministry of Construction Industry CJ / T192-2004 standard and the oil and gas SY / T6623 standard minimum 0.2Mpa and 0.5MPa, Jiangsu Zhongxin production can reach 0.8-1.6Mpa, most enterprises to maintain the product at 0.5MPa.

Ceramic tile lined pipe compared to pure alloy tube cost advantage:

The higher the price of the alloy, the more the cost of using the double metal composite pipe.

| Flexure Strength | Tensile Strength | Elongation | Cross Section Stretch Ratio | Impact Toughness | Hardness of Wearable Layer | Hydrostatic Testing Pressure |

| MN/㎡ | MN/㎡ | % | % | J/c㎡ | HRC | Mpa |

| >610 | >700 | 5 | 5.1 | >15 | >38 | 5.6-12.9 |

Alloy Cast Iron, Alloy Cast Steel, General Clad Steel Pipe and Cast Stone Pipe:

1. Good wear-resistance, giving full play to wear-resistance of high chromium cast iron.

2. Withstanding high pressure:

Bimetal cladding pipe and bend can be used for any pressure rating. Close bonding of outer and lining by adopting special process make cladding interlayer molten-joint to ensure reliable operation.

3. Good mechanical impact and thermal impact resistance property.

4. Convenient in connection for installation:

Bimetal cladding pipe and bend can be cut and welded as you like.